Product SpotlightTested: Vredestein tyre wear

How many hours are they good for? It’s a fair question to ask when it comes to tractor tyres. Investing in a big chunk of rubber for your machine comes with no small price tag. So you need them to not only perform but to keep on performing for a good slice of time.

We're big fans of the Vredestein Traxion tractor tyres. They work. Really, really well. But if we want to focus down on the time served in the field (and on the road)... just how well do they last?

An Exhaustive Methodology

How do you test longevity in tractor tyres? Slowly. It takes time. The boffins at DLG patiently conducted this particular test over a period of 15 months.

A quick word about DLG is needed at this point. Based in Germany, they’ve been around since 1885 and are widely respected as one of the world’s leading agricultural science centres. They focus on food and agriculture, developing comprehensive and systematic testing across both industries. With some 25,000 members, they’re plugged into all the experts and right places. What does this mean to you? It means if you see the ‘DLG Approved’ symbol, you know the product has been through some rigorous, independent testing and is as good as it says it is.

Back to this specific test. For it to be valid, it had to reflect wear behaviour in real world conditions. A mixture of on-road and in-field testing was needed, reflecting the differing conditions the tyres faced. The rising number of transport tasks on the road with agricultural vehicles and the more rapid tyre wear associated with hard-surface operation made this split crucial if accurate conclusions were to be drawn.

5 Identical test machines were used. All John Deere 6215R. 2 of these machines had 600/70R28 sized Vredestein tyres fitted to the front axle. On the rear, Vredestein 710/70R42 sized tyres were fitted. The other John Deere test machines had the same sized tyres from a reference (premium competitor) brand attached.

To track and determine the split of work between in field, transport and road tasks, plus the idle hours, each John Deere was fitted with a JD Link System. A pretty fancy bit of kit, it provided real working data for the duration of the prolonged testing period.

Using the JD Link System also allowed DLG to define the operating hours as either idle hours, operation time at low working speed (eg. field work) and operation time and high working speed (eg. transport on the road).

To track tyre wear, DLG developed a defined measurement procedure so as to ensure the compatibility of tyre wear results across the test machines and tyres. This was achieved by drilling holes into the lugs of the tyres. These holes were then filled with measuring pins, effectively acting as depth stops.

12 measuring points were used to define the tyre circumference. This allowed a statistical inspection, not only around the entire tyre circumference but also the wear behaviour in both transversal and longitudinal direction.

This all sounds rather scientific and in-depth doesn’t it? Which is good. You can rest assured DLG approaches their testing with the level of efficiency the Germans are well-known for. To what we can learn…

The Small Details of Big Tyres

The test machines were split across two contracting firms and each machine had similar operating hours. (Originally six machines had test tyres fitted to them however one showed a significantly different operating profile so was deemed to be out of range and excluded from the test results).

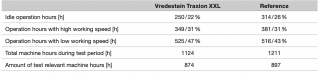

For the 5 tyre sets now being compared, the overall split of time operating at low speed and high speed was remarkably similar, as shown in the table below.

With the hours/% splits being statistically similar enough, DLG could extrapolate the data and run the math to determine a lifetime operation comparison.

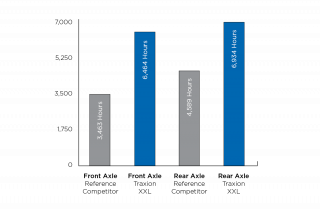

The results are telling. The reference tyres on the front axle should achieve 3463 hours. By comparison, the Vredestein will achieve 6464 hours, a difference of 87%. For the more expensive rear axle tyres, the reference tyres get 4589 hours. The Traxxion XXL will keep working past that, achieving 6934 hours or a total of 51% longer.

Establishing Value

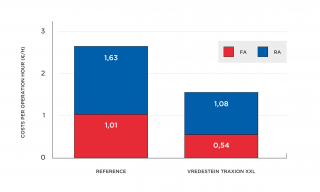

As with all things, differences become real when grounded in $. Or in this case, Euros. There are always regional and seasonal price discrepancies in play but the DLG team managed to nut it all out. The result was an average Euro 11,000 for a set of tyres, for both the reference tyres and the Vredesteins.

Armed with that knowledge, you can pretty easily turn the test results into something that illustrates real $ benefits. A bit like this really…

Final Thoughts

This latest testing from DLG adds to the growing body of evidence in support of Vredestein tyres. In independent tests, we know they have been proven to work more efficiently than competing brands. We also now know they last longer. It makes for a compelling argument especially when we factor in they’ve been proven to perform in NZ conditions.

So there we are. Vredestein Traxion. They work exceptionally well and they last exceptionally well. Seldom do you get both of these qualities together. We can’t say more than that really. They really are very impressive.

Prove the benefits of Vredestein today.

-

Topics:

- Tyre Tests

More tips and articles

Tyres for Electric Vehicles

Product Spotlight:

Maxxis HT780 RAZR HT